Compact Bakery Plant

Product Details:

- Material Ion, SS

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Human Machine Interface

- Voltage 440 Volt (v)

- Warranty 1 Year

- Click to View more

Compact Bakery Plant Price And Quantity

- 1200000 INR/Unit

- 1 Unit

Compact Bakery Plant Product Specifications

- No

- 440 Volt (v)

- Ion, SS

- Semi-Automatic

- 1 Year

- Human Machine Interface

Compact Bakery Plant Trade Information

- 2 Unit Per Month

- 2 Months

- All India

- ISO-9001:2000 Certified Company

Product Description

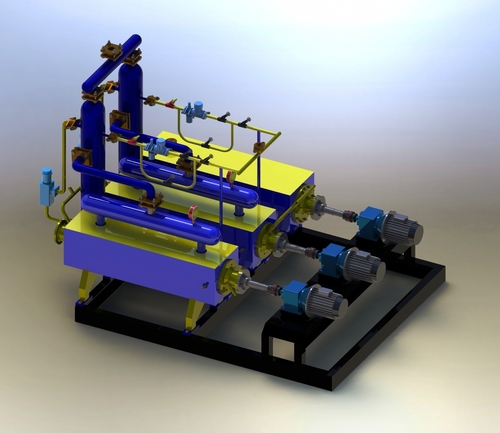

We are counted amongst the eminent manufacturers and exporters of a comprehensive array of Compact Bakery Plant. Our diligent professionals make use of the best quality components and modern techniques to manufacture this plant in compliance with set quality standards. Offered plant is extensively used in shops and restaurants for kneading flour and baking cakes,pastry and bread. In addition, we provide this Compact Bakery Plant in diverse specifications as per the specific demands of the clients.

Key Features:

- Robust design

- Hassle-free functionality

- Easy installation

- Negligible maintenance

A margarine is made up of an oil phase and an aqueous phase. The oil phase is a blend of refined oils which has been made up so that the final product will have the correct texture and solid fat content and melting point. Oil soluble additives such as colours and flavours and emulsifying agents are combined with it. The aqueous phase is generally made by blending together water, brine and dairy product. The brine is added in sufficient quantity so that the salt content of the final product is about 2-2.25%.

The production of shortening is similar, except that these contain no aqueous phase. Unlike margarine, however, they generally contain air, usually about 12% to 22% depending on the product. This air content is not very important except that the shortening is whiter in colour when it is aerated. It seems to have little effect upon performance. Because there is no moisture or salt present in a shortening the equipment can be constructed of mild steel.

Using these methods, it is possible to manufacture margarine and shortening and fat for specific uses such as frying, ice cream, toffees. Each product is differently designed for each specific application.

Product details

|

Operation Mode |

Automatic |

|

Condition |

New |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+